RePURpose

Background:

Polyurethane (PUR) is an indispensable plastic material used in a variety of products - from insulation materials, mattresses and shoe soles to components in wind turbines and aircraft as well as life-saving medical devices. More than 16 million tons of polyurethane is used annually, a consumption expected to increase rapidly in the future. Currently, only a few methods for recycling polyurethane exists, despite the high value of this material compared to other plastic materials. In addition, these methods provide a recycled product where the original properties of polyurethane are lost. This means that our current management of end-of-life polyurethane products is not sustainable and future-proof.

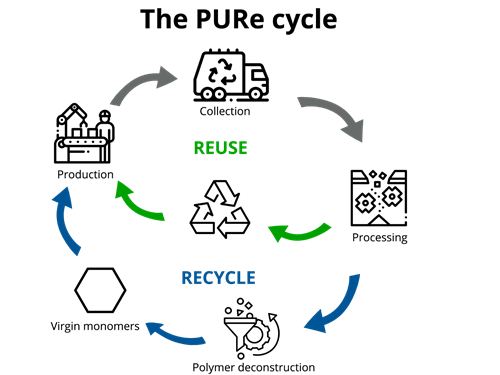

RePURpose will focus on innovative technologies for recycling of PUR. The technologies, which will be developed in RePURpose, cover recycling through innovative granular methods (ReUSE) and recycling via chemical restoration of the material's original building blocks, called monomers (ReCYCLE).

ReUSE:

ReUSE works with the recycling of the production waste that occurs at the individual manufacturer of PUR products. Production waste is a pure, homogeneous and well-defined flow of material of the same high value as the finished products. If the production waste can be traced back into production, it will create value instead of leaving the production plant as waste. The goal of ReUSE is to develop a simple method and an associated process plant, based on a new granular technology that allows the production waste to take part of the production of new products. At the end of the project, it is expected that prototypes of ReUSE process plants will be installed by partners in the project.

ReCYCLE:

ReCYCLE works with recycling polyurethane products coming back from consumers. These end-of-life products will consist of many different PUR types and ReCYCLE must be a platform which can handle as many of these types as possible. ReCYCLE is focused on developing innovative and mild chemical reaction conditions that can degrade polyurethane. The products of this degradation will mainly consist of the building blocks, called monomers of polyol and isocyanates, from which the products were originally made. Thus, ReCYCLE will be able to supply virgin material to the PUR value chain, material that can be made into any new high value product.